Create a Dieline From a Flattened Box Scan – How To Save a Bad Dieline

- Mar, 11 2012

- By Clay Butler

- Package Design, Tutorials for Beginners

- 8 comments

How I Saved My Client From A Bad Box Dieline and Why I’ll Never Trust Anyone’s Dieline Again…Not Even My Own!

Material for This Tutorial: Download the Layered Illustrator Edible PDF of this Box Dieline to see how it’s done. I embedded the scanned box image so the file is 26mb – so be patient. The plus side is that you can open it in Illustrator and all the components are guaranteed to be there.

My client was importing mandarin oranges from China. The boxes they came in would also be printed and manufactured in China. The trouble was, the manufacturer refused to release the dieline so I could design the box. Their reasoning was that they were afraid someone would “steal” the dieline. Besides being absurd, their desire to protect the dieline from theft made it impossible to complete the design work.

To anyone used to U.S. standards of workmanship, customer service, and professional expectations, this stance was quite a shock. However, I have enough experience with manufacturing in China to know this situation is not unusual.

In China, because their industrial revolution is still so young, they are still working out their cultural definitions of what professional means. So you’ll have one factory making top of line electronics in modern clean rooms indistinguishable to what you’d find in Silicon Valley, and another that looks like a turn of the century sweatshop. Some have the latest and greatest equipment and software and are highly automated, and some are doing everything by hand with whatever dated equipment they can scrounge up. Some will send out defective products and tainted food and drugs without a second thought, while others are aligned with US and European safety standards. Some won’t hesitate to steal all your intellectual property and compete against, and some protect their client’s IP as if it were their own. And some deliver print quality, accurate, digital dielines in PDF or AI format while others will send you scanned pencil drawings they made on some notebook paper. That last part is not a joke. You may get a pencil drawing for your specs. And the weird part is, the pencil drawing may be the more accurate file.

This is what makes it so hard from a designer’s standpoint. I never know what I’m going to get and my client’s have the same anxiety.

So back to the box company. After much feet dragging, and with the threat of losing the account entirely, they did release the dieline.

Below is the dieline they sent me.

Dieline Received From Chinese Box Manufacturer

The dieline looked a bit off, but I figured I just wasn’t seeing it the right way and it would actually come together when assembled. So I started designing on top of the Illustrator file they sent me.

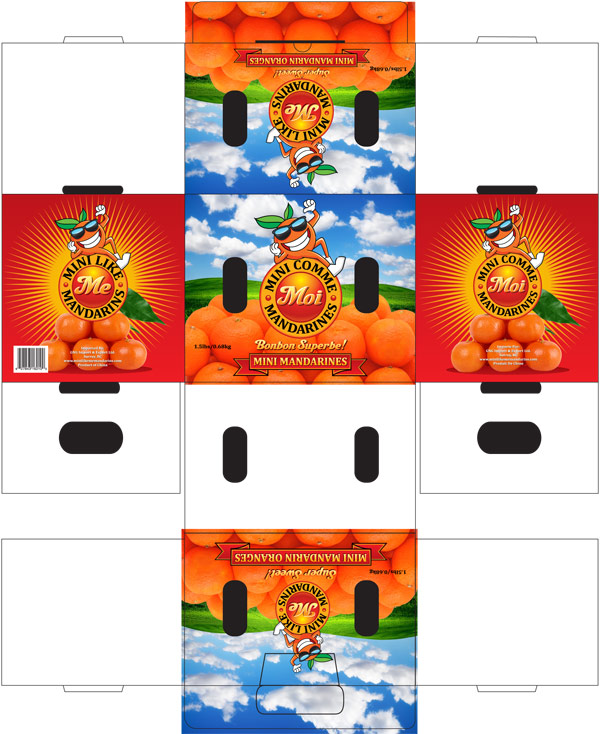

Bad Dieline From Chinese Box Manufacturer

After I completed the design and sent a proof to my client, he also agreed the dieline looked a bit off. So I printed out a miniature and folded it together. It then became apparent why it looked off as the box could not be assembled. The front panel was shorter than the back ,which made the top close at a slant. Plus the two side panels were at least 20% too wide so they completely eclipsed the front panel. It was a total disaster. What made this even more baffling was that apparently someone had already used this dieline for a box before. How could they not know that this dieline was completely unworkable – except for perhaps MC Escher?

Bad Dieline Prototype From Chinese Box Manufacturer

It was now apparent that the printing company, besides being paranoid about having their dielines “stolen”, couldn’t even make a correct dieline to begin with.

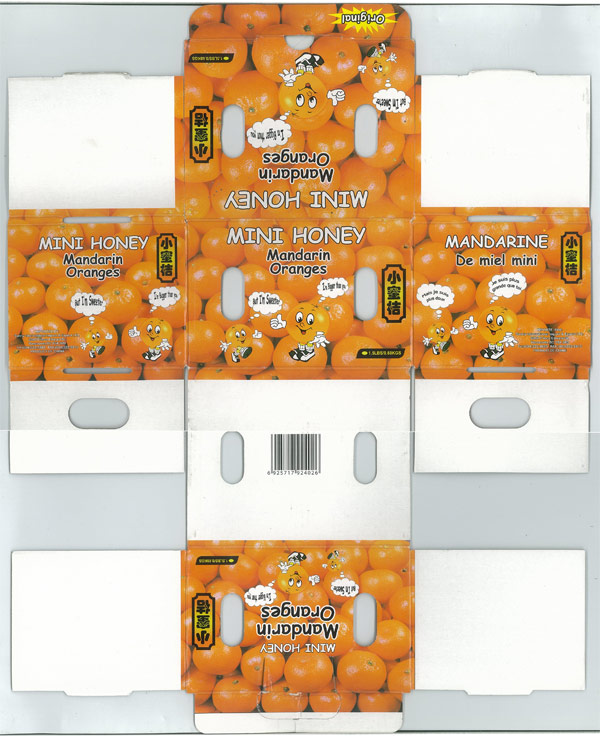

So we went to plan “B” which was to have my client email me a full 300 dpi resolution scan of a flattened orange box that he had bought at the supermarket. This would guarantee that our new box would work. The box was really big so he took it to a Kinkos type place and had them scan it in two pieces. I then combined the two scans in Photoshop.

300 DPI Scan of Client’s Flattened Orange Box

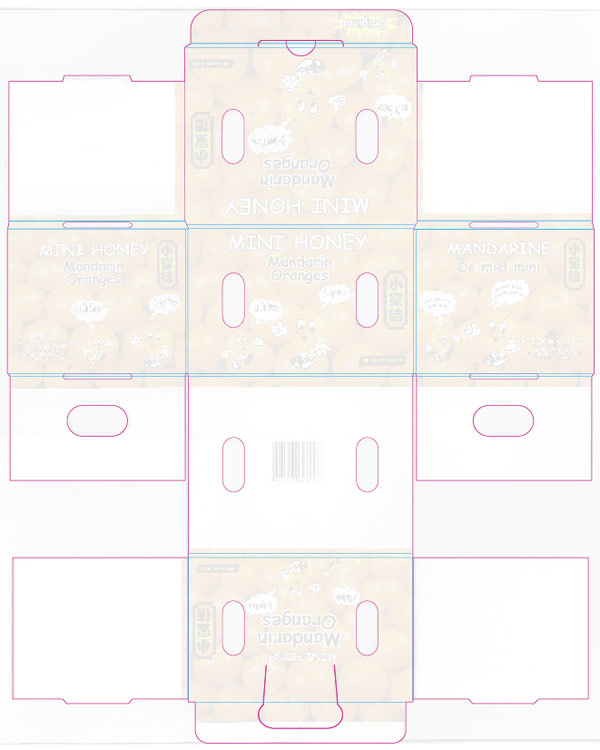

300 DPI Scan of Client’s Flattened Orange Box with New Dieline

Then I opened up a new document in Illustrator, placed the new dieline image, and began to make my dieline. Now the boxes are stamped out on big machines and then folded, filled with oranges, and then shipped overseas, so the box was off a bit here and there. I could tell where the off-ness was due to a bad cut or distortion caused by shipping and compensated for that. If five out of six sides were straight with a rounded corner, and one side was at a slight angle and not as rounded, I just assumed that was an anomaly and made that one match the others.

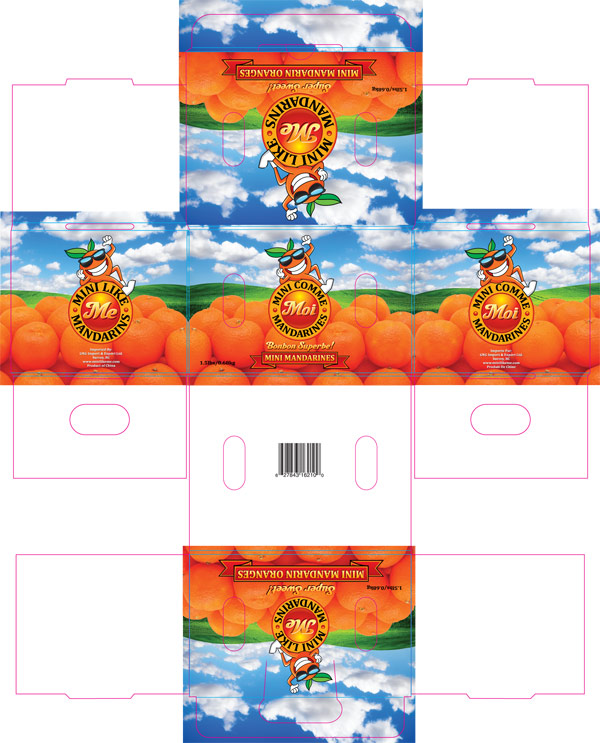

Finshed Orange Box with Dieline

When I finished the dieline I printed it out to make sure it worked, which it did, which was no surprise as it was a tracing of a box that we knew worked.

I then completed the design, proofed it with my client, and then sent that on to China.

This is precisely why I never trust anyone’s dieline, not even my own, and especially not one from China. Always print and assemble first. It’s the only true way to know for sure if you have a good dieline or a bad one.

Looking for a Package Designer?

If you need someone to design your product packaging give me a call at 866-477-9029 or email me.

File Under: How to Create a Dieline by Scanning a Flattened Box and Then Tracing in Adobe Illustrator – How to Fix a Bad or Inaccurate Dieline – Fixing Dieline Problems Wrong Dimensions

Debbie Griffith

Thanks for the interesting and educational information.

mona brown

Great information for my future as graphic designer , I won’t forget your instructions check and recheck.

Adrian

Hello Clay.

There is a lot of real life stuff they won’t teach you at school and all your articles are great approach on that. Thanks a lot for all the info really!

I just wanted to ask a small question. Wasn’t there any problem with the fixed dieline that you sent, seeing that it was clearly different from the one the chinese suppliers gave you in the first place?

I mean, the box your client scanned could have been made by a different supplier. Isn’t there any risk on changing the templates?

Clay Butler

No risk really. From a printers point of view a box is a box. They are all printed flat on big sheets and then stamped out.They need to make a custom dieline no matter what so it might as well be one that I know works. Especially considering their dieline didn’t.

And since we were copying a mandarin box that held the same product in the same volume, there’s no worry that we’ll end up with a box that can’t fit his mandarins.

Adrian

Oh thats good to know, I had the wrong assumption that printers work with standardized dielines and designers had to adapt their artwork to those.

Thanks a lot really!

Clay Butler

Well it’s a little of both actually. Most dielines are based upon the dielines provided by the designer. However, printing companies may also have a library of stock dielines that you can use. This is really common in the label industry. So let’s say you have made the pefect dieline and it’s 2.25″ x 3.125″ with rounded corners. The printer may say, “hey you can save yourself the custom die charge if you use our stock 2.25″ x 3″ dieline”. If the 1/8″ of vertical height is no big deal, you can save your client a custom dieline charge by shaving that off your design.

Dina Hafez

Thank you for sharing these informations, it’s really helpful especially in my stage of starting to create a packaging for my final major project. Please if you have any tutorials or files that could help me to understand the dieline a bit more that would be so nice of you :)

Custom Boxes

“Box Scan simplifies the logistics game with its efficient scanning solutions. By effortlessly capturing and managing information on packages, it streamlines the process, ensuring a smoother and more accurate handling of shipments. The technology behind Box Scan elevates the efficiency of package tracking, making it a valuable asset for any operation. In the world of logistics, where precision is key, Box Scan stands out as a reliable and innovative solution